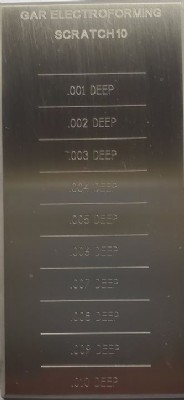

- Twelve replicated machined surface finish specimens with examples of four different machining processes: Shape-turn, ground, profiled and milled- ranging from 250 to 2000 microinches.

- The G-61 Conventional Machining MICROFINISH COMPARATOR is rectangular in shape (1 3/8" x 6") and is a nickel corrosion resistant electroformed nickel duplicate of actual machined surfaces.

- There are twelve replicated machined surface finish specimens with examples of four different machining processes: shape-turn ,ground, profiled and milled- ranging from 250 to 2000 microinches.

- The G-61 MICROFINISH COMPARATOR is supplied in a leatherette case with engineering data and instructions.

- Supplied with a Short Form Certification, Long Form Calibration Certificate available (ISO/IEC 17025:2017)

- Allow 3 Weeks for Calibration Certificate

Returns

If a comparator is purchased without calibration, it cannot be returned if the customer then has it calibrated on their own and it fails calibration. GAR will only stand behind our own, calibrated comparators.