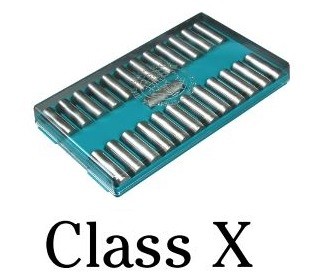

- Each set contains 25 pieces of Class X tolerance (.00004”) gage pins.

- Traceable to NIST

- Choice of two tolerances: Plus (+.00004”) or Minus (-.00004”)

- Sets consist of a center nominal size, and 12 gages larger in .0001” steps and 12 gages smaller in .0001” steps. Metric sets available in 0.01mm increments.

- Each gage is inspected and has a 2 microfinish or better.

- Heat treated and through hardened to 60-62 Rockwell C

- All pin gages over .060” or 1.51 mm are laser marked with size direction of tolerance and serial number for traceability.

Meyer - MG-25 Plug Gage Sets - Class "X" - 25 Piece - .01mm Increments - (Metric)

Click here for INCH sizes

Filter Products:

Enter NOMINAL (center) Pin Size (4 digit number with decimal):

Tolerance Direction :

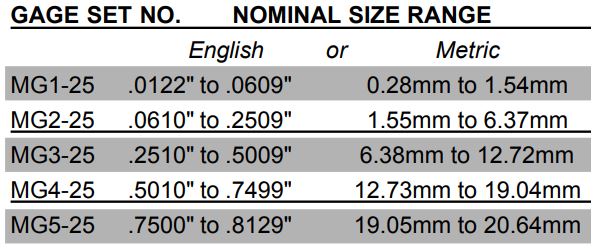

| Item No. | Size Range | Tolerance Direction | Our Price | QTY |

|---|---|---|---|---|

| MG1-25PMETRIC | 0.28mm - 1.54mm | Plus | $470.00 | |

| MG1-25MMETRIC | 0.28mm - 1.54mm | Minus | $470.00 | |

| MG2-25PMETRIC | 1.55mm - 6.37mm | Plus | $235.00 | |

| MG2-25MMETRIC | 1.55mm - 6.37mm | Minus | $235.00 | |

| MG3-25PMETRIC | 6.38mm - 12.72mm | Plus | $270.00 | |

| MG3-25MMETRIC | 6.38mm - 12.72mm | Minus | $270.00 | |

| MG4-25PMETRIC | 12.73mm - 19.04mm | Plus | $375.00 | |

| MG4-25MMETRIC | 12.73mm - 19.04mm | Minus | $373.00 | |

| MG5-25PMETRIC | 19.05mm - 20.64mm | Plus | $520.00 | |

| MG5-25MMETRIC | 19.05mm - 20.64mm | Minus | $520.00 |

Features:

- Used as masters to calibrate measuring equipment and check linearity of comparators, micrometers, and calipers.

- These ‘Tenth Step” gage sets have unlimited applications, such as quality control inspection, prototype work and production layout.

- Inspectors select from the range of pins to find the size of a hole or slot.

- These round masters simulate a cylindrical part which, unlike flat blocks, can detect uneven wear on the tips of micrometers and calipers.

- The thin “line” of contact detects uneven face wear better than flat gage blocks with large contact area.