A simple and innovative Digital Readout for Optical Comparators, Measuring Microscopes, or any Metrology device requiring encoder supported measurement.

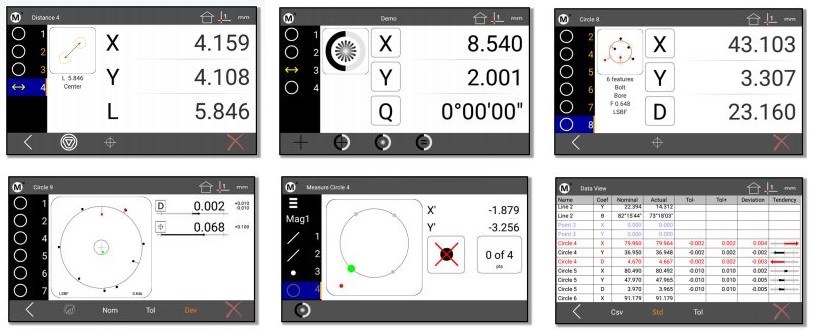

- The Mx200 is a metrology readout for performing two and three axis measurements.

- Measurements can be performed using optical comparators, measuring microscopes and a variety of other crosshair measurement systems.

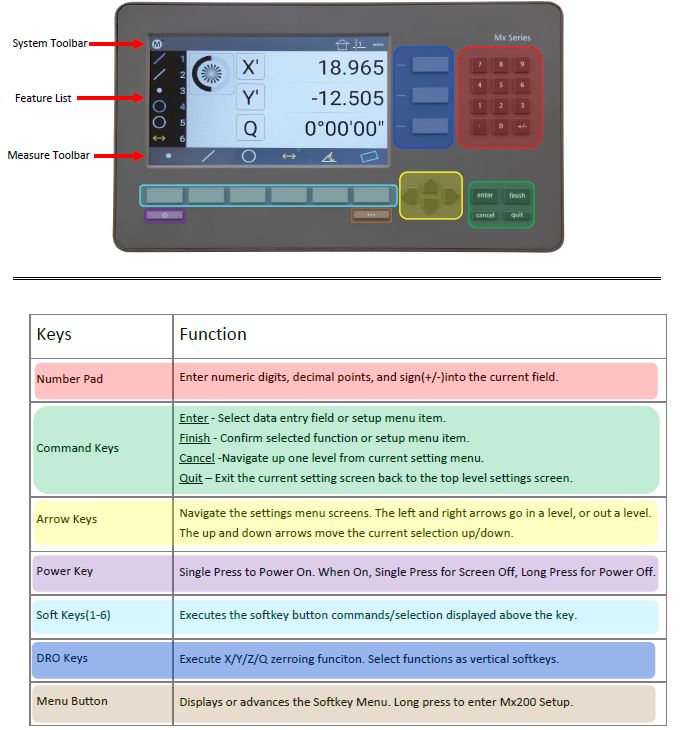

- All user interaction with the software is through the color touchscreen or through the use of softkeys and function keys on the rubberized keypad.

NEED A QUOTE? Call or Email us with the information below:

- The Make and model of the Comparator

- The make and model of the current DRO and type of connection (ex . 7pin) from the DRO to the Comparator

- The Axis configuration: XY or XYQ (optional Q is for the protractor)

- Do you need Geometric functioning?

- Will it be with with or without Optical Edge Detection?

- What type of mount you want? OEM Arm (4 Position), 1.5" RAM Ball, Desktop Stand

- Click HERE for more information on how to order