- Pitch diameter is coaxial to the cylinder portion of the gage, which projects a greater cylindrical tolerance zone than any other standard center-line locator on the market.

- Pitch diameters are calibrated, (front and back), using the universal three-wire method.

- Standard Shaft Length: .625"

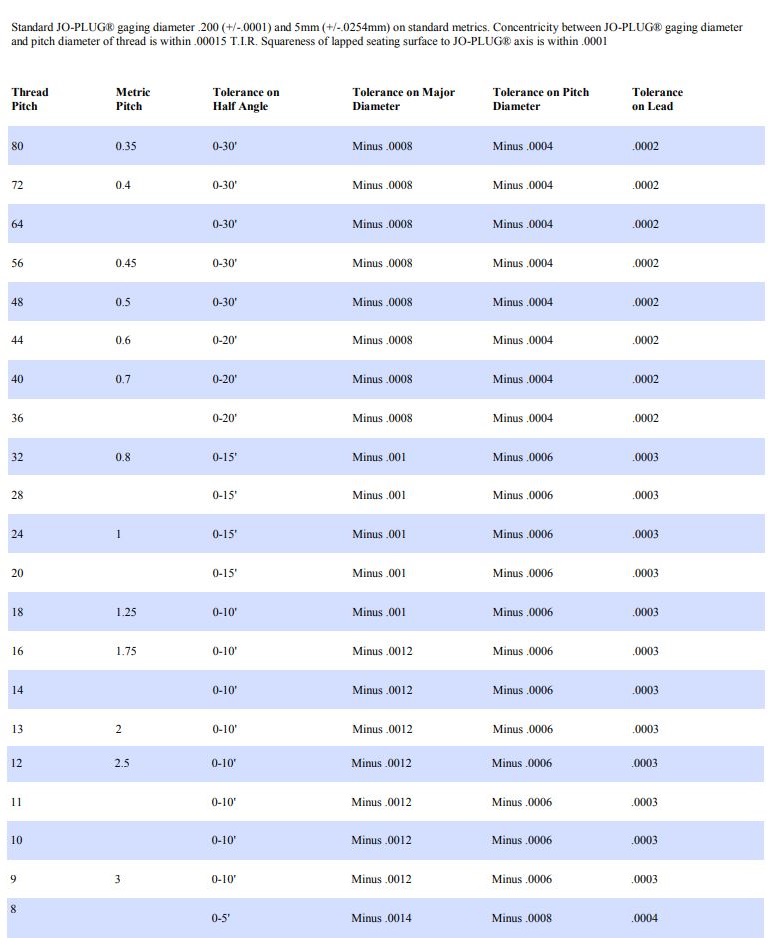

- Standard Shaft Diameter for Inch Sizes: .200" (+/- .0001")

- Standard Shaft Diameter for Metric Sizes: 5.00mm (+/- .0001")

- Concentricity between gaging diameter and pitch diameter of thread is within .00015 T.I.R.

- Squareness of lapped seating surface to axis is within .0001"

JO-PLUG® - Tapped Hole Location Gages - (METRIC Class 6H)

| Item No. | THREAD SIZE (Class 6H) | Our Price | QTY |

|---|---|---|---|

| SPE1635MT | M1.6 x .35 6H | $302.00 | |

| SPE1835MT | M1.8 x .35 6H | $332.00 | |

| SPE2004MT | M2 x .4 6H | $182.00 | |

| SPE2245MT | M2.2 x .45 6H | $224.00 | |

| SPE2545MT | M2.5 x .45 6H | $184.00 | |

| SPE3005MT | M3 x .50 6H | $148.00 | |

| SPE3506MT | M3.5 x .60 6H | $188.00 | |

| SPE4007MT | M4 x .70 6H | $124.00 | |

| SPE4575MT | M4.5 x .75 6H | $208.00 | |

| SPE5008MT | M5 x .8 6H | $114.00 | |

| SPE6001MT | M6 x 1 6H | $112.00 | |

| SPE7001MT | M7 x 1 6H | $180.00 | |

| SPE8001MT | M8 x 1 6H | $134.00 | |

| SPE8125MT | M8 x 1.25 6H | $114.00 | |

| SPE1025MT | M10 x 1.25 6H | $136.00 | |

| SPE1015MT | M10 x 1.5 6H | $124.00 | |

| SPE1225MT | M12 x 1.25 6H | $162.00 | |

| SPE1275MT | M12 x 1.75 6H | $142.00 | |

| SPE1415MT | M14 x 1.5 6H | $164.00 | |

| SPE1402MT | M14 x 2.0 6H | $144.00 | |

| SPE1615MT | M16 x 1.5 6H | $176.00 | |

| SPE1602MT | M16 x 2 -6H | $156.00 | |

| SPE1815MT | M18 x 1.5 6H | $198.00 | |

| SPE1825MT | M18 x 2.5 6H | $178.00 | |

| SPE2015MT | M20 x 1.5 6H | $232.00 | |

| SPE2025MT | M20 x 2.5 6H | $212.00 | |

| SPE2015MT | M22 x 1.5 6H | $252.00 | |

| SPE2225MT | M22 x 2.5 6H | $232.00 | |

| SPE2402MT | M24 x 2 6H | $246.00 | |

| SPE2403MT | M24 x 3 6H | $226.00 |

Features:

- Pitch diameter is coaxial to the cylinder portion of the gage, which projects a greater cylindrical tolerance zone than any other standard center-line locator on the market.

- Pitch diameters are calibrated, (front and back), using the universal three-wire method.

- Standard gaging diameter is .200 (+/-.0001)

- Concentricity between gaging diameter and pitch diameter of thread is within .00015 T.I.R.

- Squareness of lapped seating surface to axis is within .0001