Features:

- Pitch diameter is coaxial to the cylinder portion of the gage, which projects a greater cylindrical tolerance zone than any other standard center-line locator on the market.

- Pitch diameters are calibrated, (front and back), using the universal three-wire method.

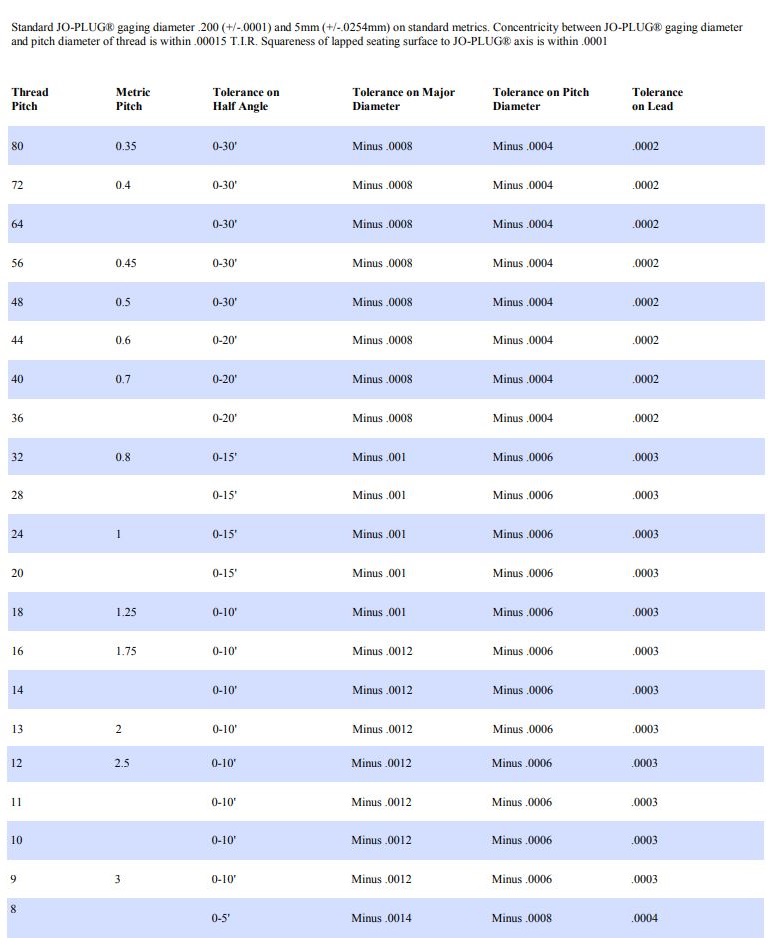

- Standard gaging diameter is .200 (+/-.0001)

- Concentricity between gaging diameter and pitch diameter of thread is within .00015 T.I.R.

- Squareness of lapped seating surface to axis is within .0001

- Significant is the solid thread form with a pitch diameter that is calibrated, front and back, using the universal three-wire method.

- The JO-PLUG® centerline location plug pitch diameter cylinder is coaxial to the cylindrical “stem” of the gage, establishing a parallel datum axis within which MMC is established.

- Basic Position and Basic Profile dimensions, which define the orientation and location of the related tolerance zones, are established using CMM or Laser Tracker software.

- True position of the tapped hole, as well as perpendicularity and projected tolerance zone of the threaded hole is established.

JO-PLUGS® are threaded and inspected in accordance with the International Standard ISO/IEC 17025:2005, which meets the general requirements for the competence of testing and calibration laboratories. This laboratory also meets the requirements of ANSI/NCSL Z540-1-1994 and any additional requirements in the field of calibration.