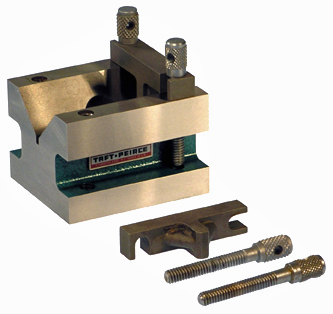

- BALL BEARING "V" BLOCKS Overcome Production or Set-Up Difficulties Inherent in Plain V-Blocks. Overcomes Geometric Limitations.

- Enables you to inspect and detect out of round conditions and lobes with no damage to parts and no damage to blocks

- Accuracy of Balls: 25 millionth of an inch sphericity on small and medium set. 50 millionths of an inch on large set.

- Overall accuracy of matched pairs +/-5 microns.

- Balls Rockwell C-62 - Surface finish 0.2 microinches.

- Calibrated balls are certified.

- Class 40 cast iron, used on base and housing, is heat stabilized and seasoned.

- Spacers are hardened through and precision ground by pairs.

- Pair of blocks assembled using metrology equipment.

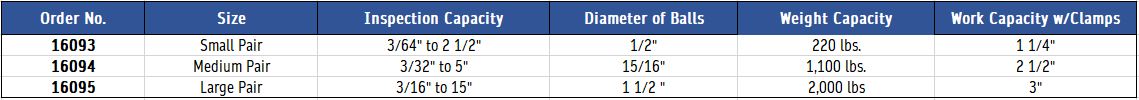

- AVAILABLE IN 3 SIZES WITH RANGES OF: 3/64"-2 1/2"; 3/22"-5"; 3/16"-15" AND UP.

- SOLD IN MATCHED PAIRS COMPLETE WITH CLAMPS (for use when machining).

Flexbar - Ball Bearing "V" Blocks (2) - w/ clamps

Filter Products:

Clamps:

Features:

Special Functions

- Balls undergo slight elastic deformation when parts are loaded on. Hence parts will not be damaged while being inspected or produced.

- Detection of lobes and superimposed lobes made easy.

- Easy readjustment of balls which provide new bearing points.

- Handles diameters up to 15 inches.

- Increased contact area due to special geometric spacing of balls in blocks.

- 8 contact points per pair of blocks share load distribution.

- Balls are self-aligning and hard wearing.

- 1 each precision spacer per block provides 2 different angles per pair.

- Simply turn each block 90° and inspect component using both angles.

- Special inspection set ups using cylinder squares now possible.

IMPORTANT NOTE: BALLS ARE FIXED IN BLOCKS AND ARE NOT DESIGNED TO ROTATE IN USE.